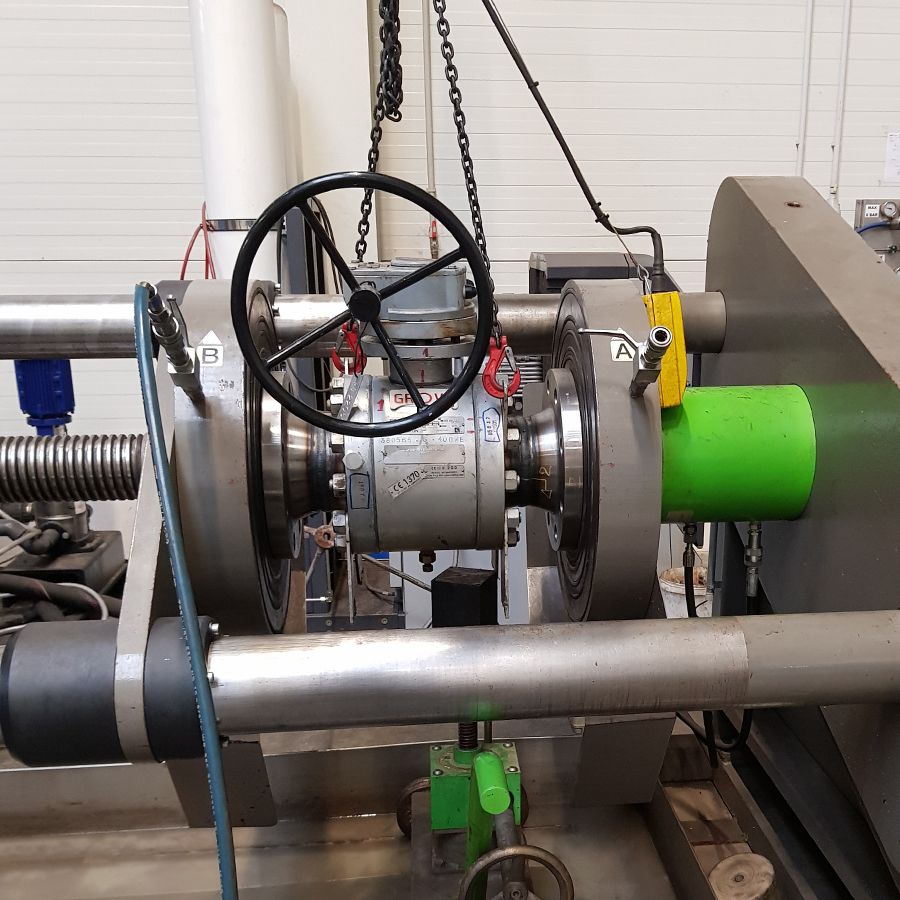

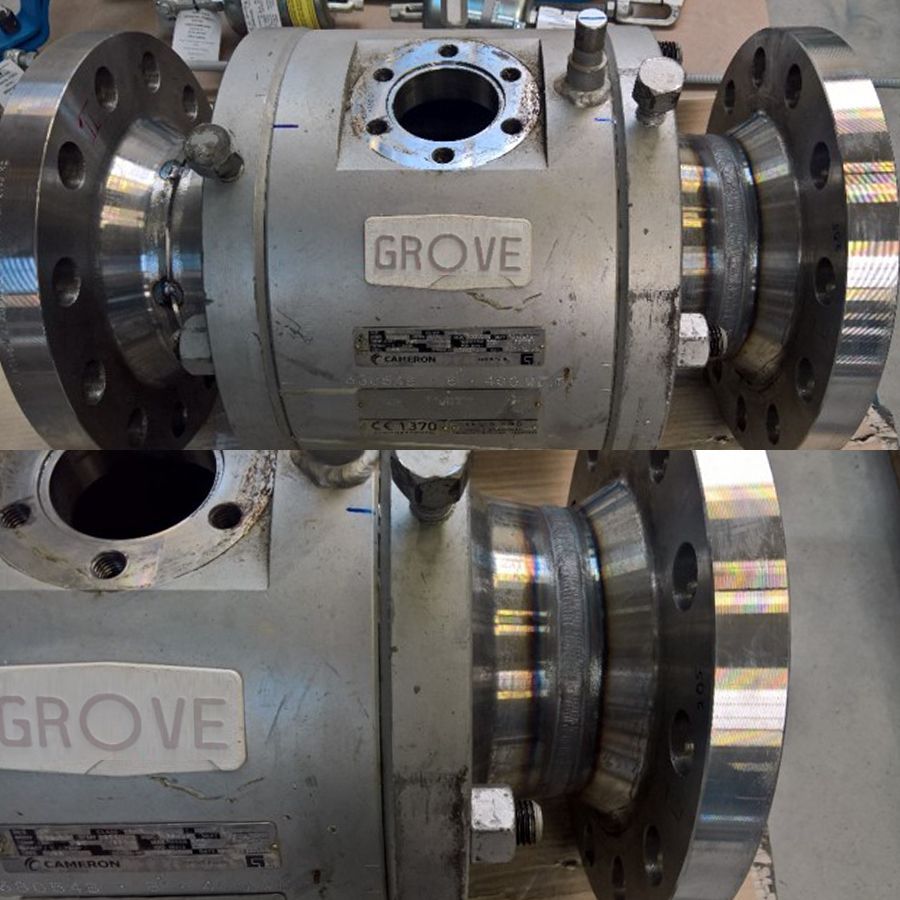

After the successful renovation of 37 pcs of GROVE ball valves as a part of extensive revitalization of distribution shaft of Čepro in Nové Město another phase of revitalization took place, namely the overhaul and modification of 19 pcs of DN150 – DN300 ball valves in emergency storage.

The aim of the overhaul wasn´t only the repair itself but also the change of the connection from the welding design to the flange design to Čepro will be able to carry out quick replacements in the future without the necessary extraordinary measures. This leads to the minimization of necessary stop of operation and the possibility to use the distribution network as much as possible.

The order was very demanding on welding, welding documentation and non-destructive testing. It included the renovation of balls by a new type of surface (ENP) and a complete renovation of parts. The last phase was the installation of ball valves in the pipeline network with precisely defined torques using Hytorc tightening tools. This requirement results from the high requirements for the environmental safety of flanged joints, where it is necessary to prevent any leakage.